3D printing and electrospinning at the service of tissue engineering

3D printing and electrospinning at the service of tissue engineering

- Principal Investigator: Dr hab. Eng. Izabella Rajzer, University of Bielsko-Biała

- Project title: Layered scaffolds for nasal cartilages reconstruction fabricated by 3D printing and electrospinning

- Funding scheme: SONATA BIS 5, announced on 15th June 2015

Damage to the cartilaginous tissues of the nose poses a serious problem not just for the patient, but also the laryngologist and the plastic surgeon. The nose gives personality to the face and may make it ugly or beautiful; it is made up of bone and cartilage covered with skin. Due to its specific structure, cartilage has limited regenerative ability. The search for new materials that could facilitate the reconstruction of the damaged tissue has led to the development of a promising new interdisciplinary field known as tissue engineering, which aims to reconstruct and restore the function of damaged or removed tissues and organs. In broad strokes, cell samples are taken from the patient and cultured on a special substrate in the lab. The material serves as scaffolding for the new cartilage and is dissolved once the latter has acquired the desired mechanical properties. The tissue is then transplanted into the damaged area of the patient's body.

The substrate-scaffolding should have a spatial, porous structure that would allow cells to build their own matrix, enable penetration of the forming tissue, and facilitate the delivery of nutrients. The pore size should be adjusted to the growth of specific tissue cells. In addition, the physical, chemical, and mechanical properties of the biomaterial, which will not change once the tissue has healed, should likewise mirror those of the cells in question. The scaffolding must be able to biodegrade once it has played its role, and the products of its degradation should not be harmful or induce inflammation. Many laboratories around the world have been investigating the possibility of using composite substrates for tissue reconstruction, but their products still fail to meet the above requirements and adequately stimulate tissue growth.

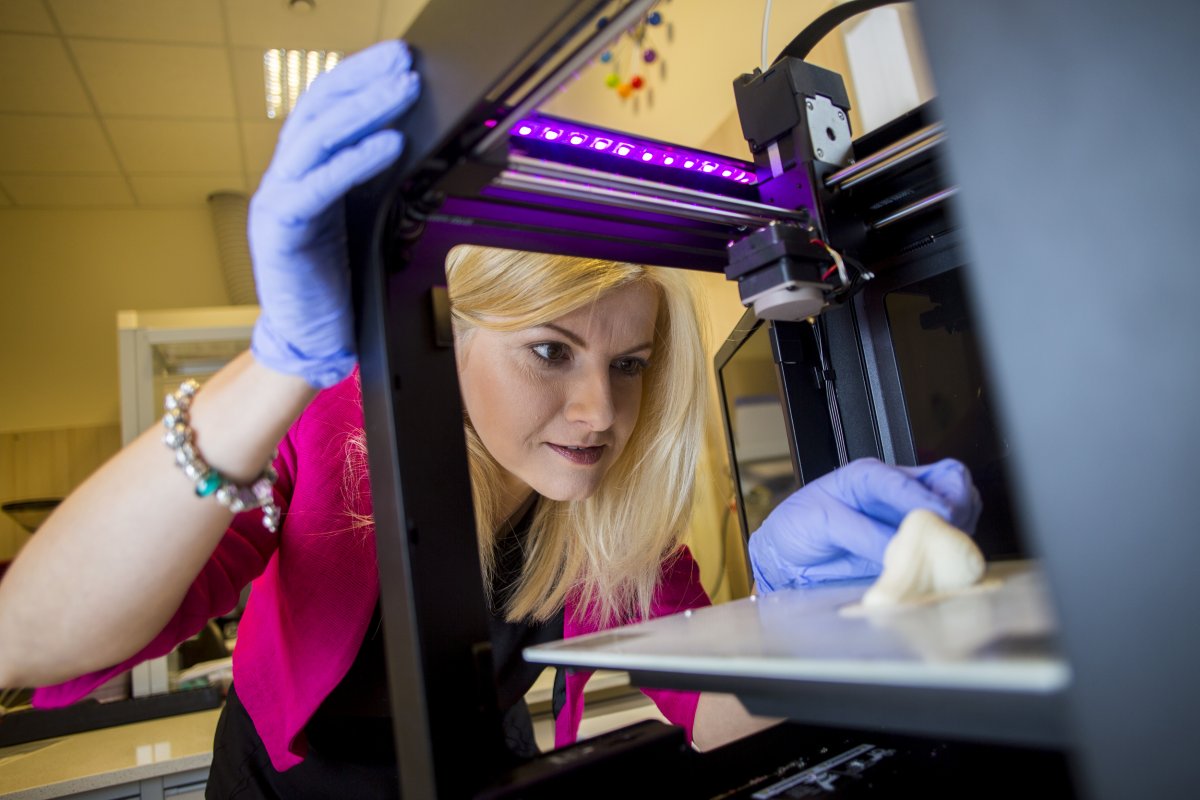

The objective of the project is to develop layered, spatial substrates for the reconstruction of the cartilaginous tissue of the nose. It uses two different methods (3D printing – the FDM technique, and electrospinning) to produce hybrid substrates that, on one hand, ensure the mechanical stability of the porous construct, and, on the other, stimulate the chondrocytes to grow and build the tissue thanks to their nanofibre structure and modification with active agents. The hybrid biomaterials thus produced combine two or three different polymers (polyesters and hydrogels), growth factors and drugs. Owing to the modification of the 3D (FDM) printer purchased in the framework of the project, we will be able to print out spatial, three-dimensional substrates with the use of composite filaments created in our laboratory and modified with various active agents. Printing with polymer filaments (as compared to the traditional methods) will also allow us ensuring the appropriate composition of the substrate by giving us the chance to select and combine filaments while printing. Modifying the scaffolding by adding nanofibres with growth factors and drugs will help create an auspicious environment to stimulate the growth of cells and promote the process of cartilage formation.

Dr hab. Eng. Izabella Rajzer

Graduate of the Faculty of Materials Science and Ceramics at the AGH University of Science and Technology in Kraków. In 2006, she successfully defended a doctoral thesis in the field of materials engineering. In 2007-2008, she completed an internship at the Institute for Bioengineering of Catalonia (Barcelona, Spain) in the group of Professor J.A. Planell. In 2016, she defended a habilitation thesis devoted to polymer-ceramic biomaterials designed to assist the regeneration and mineralisation of bone tissue. She manages six research projects financed by the Ministry of Science and Higher Education and the National Science Centre. She currently works as Associate Professor at the Faculty of Mechanical Engineering and Computer Science at the University of Bielsko-Biała.

Date of publication: 5th Jan, 2018

Facebook

Facebook Twitter

Twitter LinkedIn

LinkedIn YouTube

YouTube Instagram

Instagram